RoboplazmaTM

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Our Product - Roboplazmatm

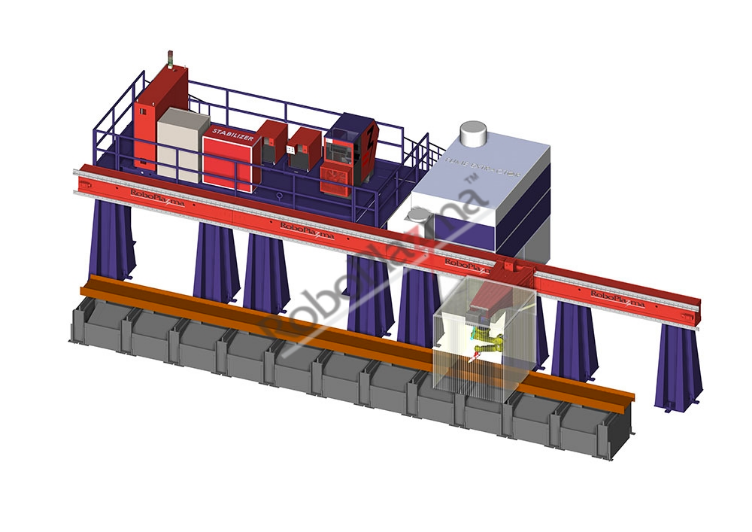

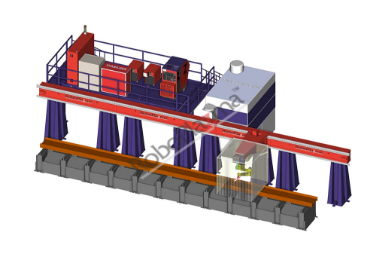

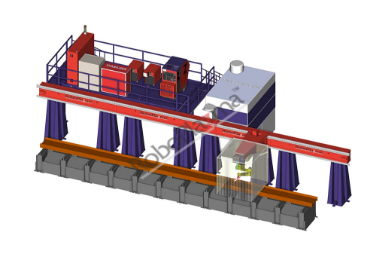

Universal System

The RoboPlazma™ Universal System is a world first double work zone with integrated moving enclosure for various 2D and 3D cutting & welding.

3D System

This RoboPlazma™ solution is literally like the I Phone of structural steel processing machinery. With RoboPlazma™ both hardware and software are modular and scalable

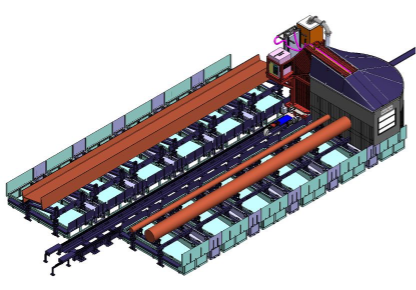

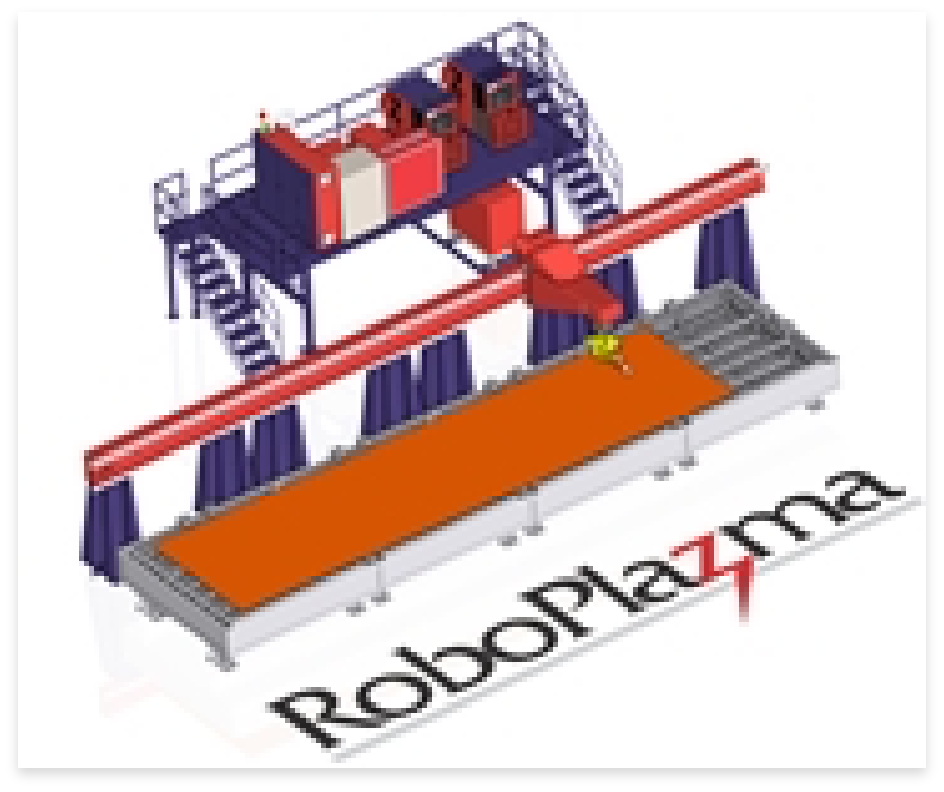

Beam System

RoboPlazma™ Beam System is an ideal solution for small, medium and large fabricators that are looking for a single machine solution to fabricate

Fixed Robot System

This is a cost effective modular configuration of RoboPlazma™ system for a small job envelope with a Fanuc Robot mounted on fixed cantilever arm, interfaced with Plazma power source.

Hot Plate System

This is a world first. Even Siemens teams of steel plant builders were doubtful if this could be done. We were very fortunate that Jindal Stainless Steel believed in us due to our 16-year track record Plazma cutters.

Hign SpeedWelding System

The RoboPlazma™ Universal System is a world first double work zone with integrated MIG/MAG welding source and RoboSwift programming software. The System is capable of welding Structural steel, subassemblies up to 30 mtr.RoboPlazma

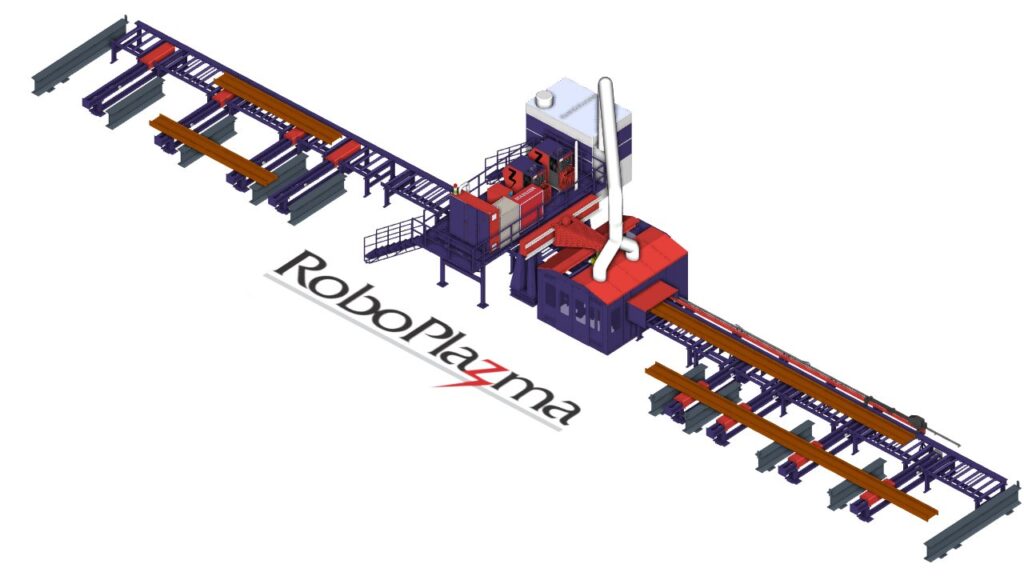

RoboPlazma™ is an ideal solution for small, medium and large fabricators that are looking for a single machine solution to fabricate Beams, Channels, Angles, Tubes, Pipes and also have Large Plate processing covered with the same machine. RoboPlazma™ is a Shop floor tested Innovative design having 9 patents. A few of the many unique features are:

What makes us unique?

- Double work zone eliminates material handling time

- We have perfected a Vibration free Moving Cantilever design that delivers precision.

- RoboSwift is our simple 3 Click software powering a machine that grows with you Smart Modular Hardware enables system expandability.

- Unlike our competitors RoboPlazma™ replaces more than 7 individual machines ensuring capital efficiency while saving shop space.

- Independent Measuring System give high accuracy.

- IOT and Industry 4.0 compatible.

The capabilities unmatched by the competition are,

- Underside processing without additional Robot.

- All side Square tube processing.

- Large Plate Cutting 2.5 x 30 Mtr. with weld edge preparation.

- Complex geometries like Mouse Hole being processed which are not achieved by competition.

- Pipe processing.

- Practically all shapes cut on all structural steel profiles.

Get in touch to know more about RoboPlazma