PetroChemical

To be competitive in the market up gradation and onsite modifications of Petrochemical reactors is the key factor for higher throughput at lower cost. Per hour shut down cost of Refinery plant is huge. Secondly, onsite plant modification is not an easy with traditional ways, it is time consuming and not safe at all.

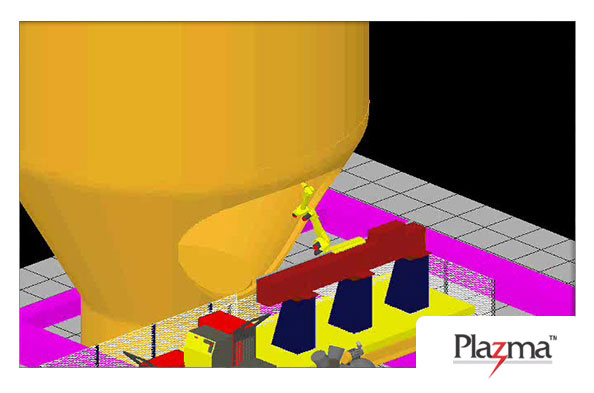

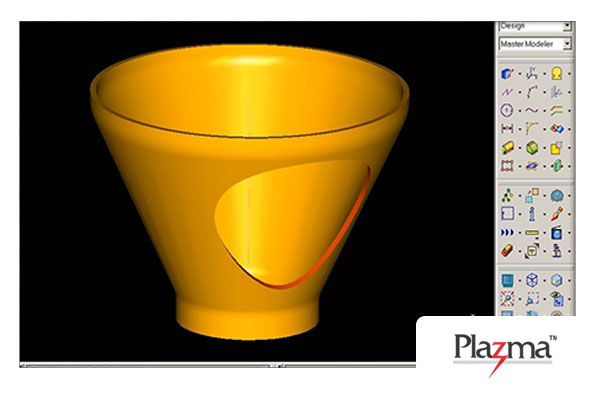

Our RoboPlazma’s system is capable for processing such complex onsite plant modifications. This system not only minimize plant shut down time but also saves huge costs. RoboPlazma’s modular hardware and intelligent software configuration makes all this possible now.

Some of major Benefits for On site plant modifications are

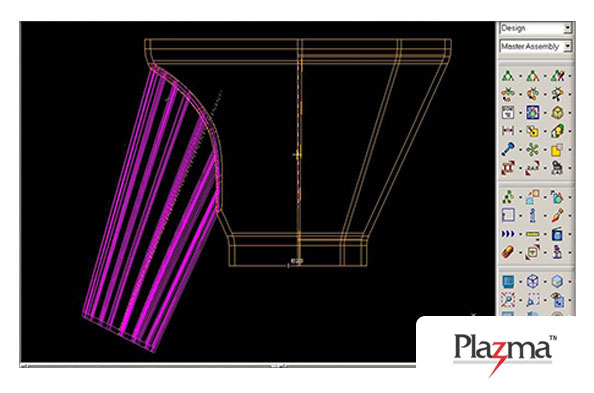

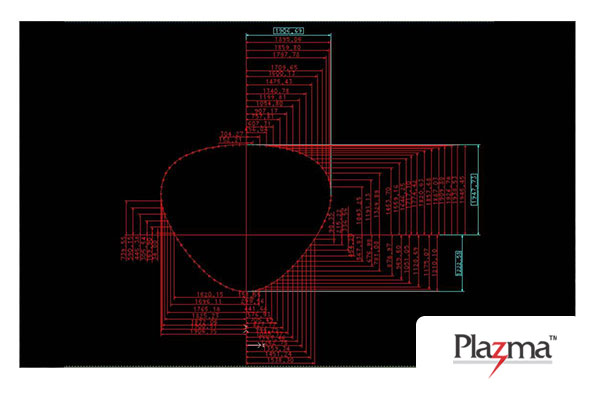

- Onsite Nozzle cut outs just in 3 days

- Matching CAD and physical data while cutting

- Cutting 60 mtr. up in the air in existing plant

- 145 mm thick shell cutting against gravity

- Reduce Plant down time

- Reduce plant shut down cost

Our Valued RoboPlazma™ customer in India had adopted this smart solution in 1996 to modify their gross root Petroleum refinery reactor and increased nozzle size. All this was achieved just in 3 days and overall plant throughput was increased by 30% higher.