RoboPlazma™ - Welding

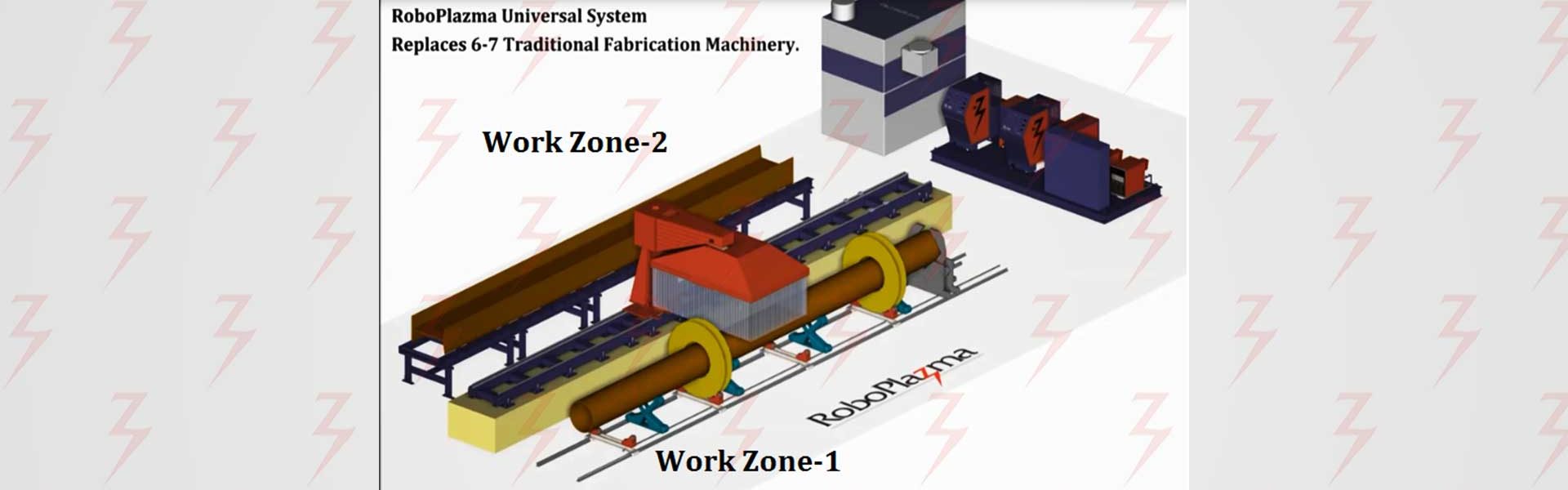

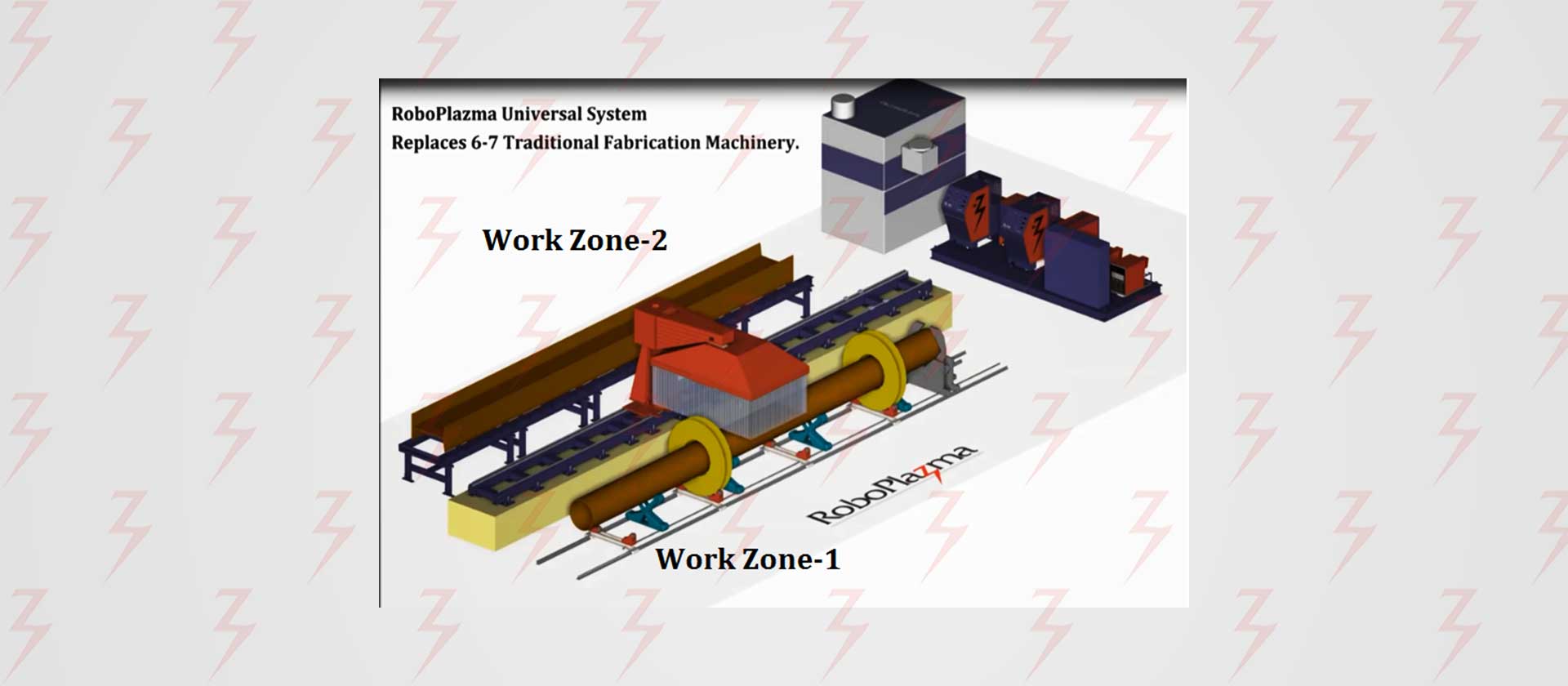

The RoboPlazma™ Universal System is a world first double work zone with integrated MIG/MAG welding source and RoboSwift™ programming software. The System is capable of welding Structural steel, subassemblies up to 30 mtr. length through separate order). RoboPlazma™ System is manufactured with highest quality standard components such as FANUC Robots, Precision Rails, Kemper, Germany fume extraction, Fronius welding source and integrated with a user friendly RoboSwift™ Software interface that allows to create different programs with minimal operator intervention. All Robot axes are Servo driven for precision movement.

Modular hardware and software design allows you to add on Plazma cutting capability to enhance utilization of the system besides cutting. This unique flexibility gives users the potential to meet multiple customer needs simultaneously.

Key Features of Universal System

- Double work zone eliminates material handling time

- High Speed MIG Welding

- Seam tracking

- Simple 3 Click Programming

- Minimum labor dependency

- Higher Utilization and throughput