Wind Mills

We are focused on making YOUR Company an Equal player with an Unequalled Edge using our RoboPlazma™ System.

A standard Wind Mill Tower height is 70 meter. Generally Wind Mill tower is fabricated in 4 sections S1, S2, S3 and S4 and assembled on site. First section S1 is being bottom of the tower has bigger diameter carbon steel plate with double beveling (30 degree) on all 4 sides.

Other sections are fabricated from 12, 14, 16, 18, 20, 24mm carbon steel. All sections has 30 degree bevel on 4 sides with root

A standard wind mill tower has following (approx.) cutting requirements.

- Straight Cutting = 880 meters

- Single and double bevel = 2100 meters

- Total Cutting & Beveling running meters = 38000 meters

- Cutting tolerance is 2mm in 70 meter tower assembly.

To achieve this huge cutting meters per day, per tower 6 to 8 conventional Oxy fuel torch stations required to be continuously cutting 24 x 7. However, after cutting plate needs to shift to beveling table for beveling where a separate cutting set and manpower is deployed. There manpower also multiplies depending upon torch stations besides gas and labor costs. Therefore, overall fabrication and operation cost goes out of limit resulting in low profit or out of business competition.

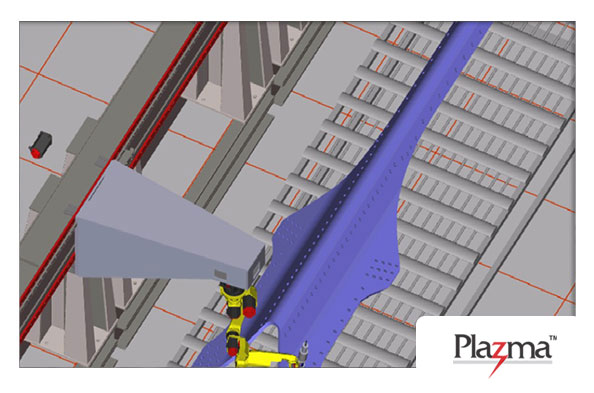

RoboPlazma™ Plate System is an ideal solution for Wind Mill manufacturer.

How does RoboPlazma™ helps you to fabricate Wind Mill Tower

- Large Plates 3.0 x 12.0mtr processing in single set saves Time, Manpower and Costs

- Auto Nesting of different shapes reduce scrap percentage

- High Speed cutting (3 to 4 times faster speed) result in high productivity

- All 4 side Beveling in single set up save material handling. No shifting of plate

- Single, Double Bevel with 2mm root is possible

- Cutting accuracy +/- 0.5 mm

- Increase overall plant throughput by reducing costs

- Faster execution of project

- Enhance profit and business growth

- RoboPlazma™ Pay back in less than 12 months