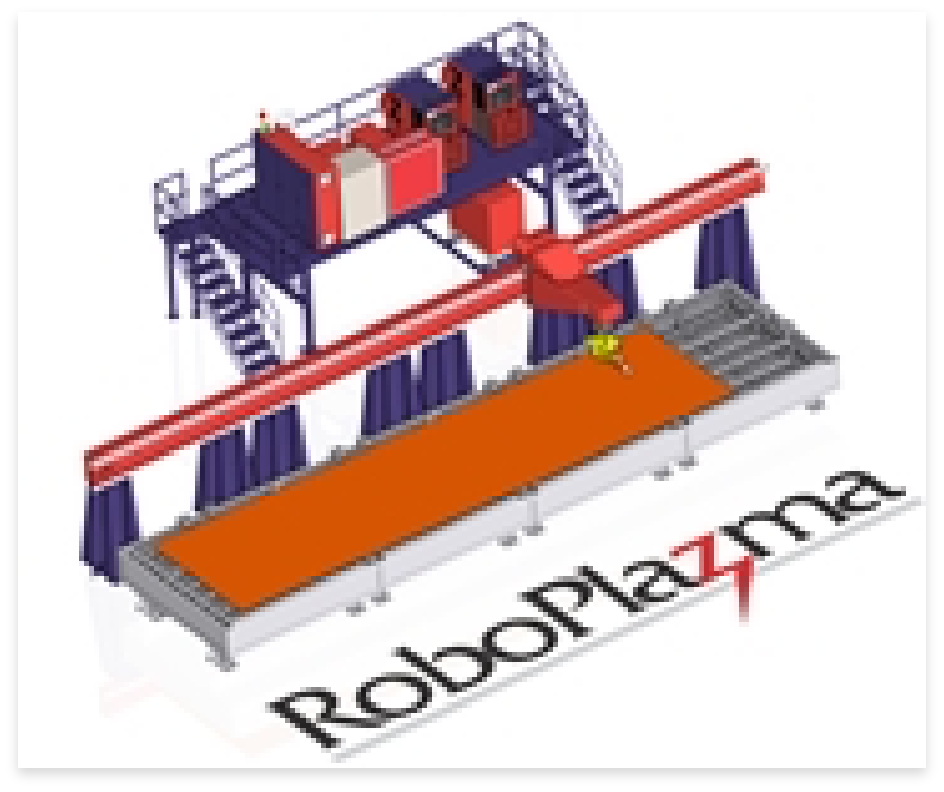

RoboplazmaTM Universal System

Our Product - Roboplazmatm Universal System

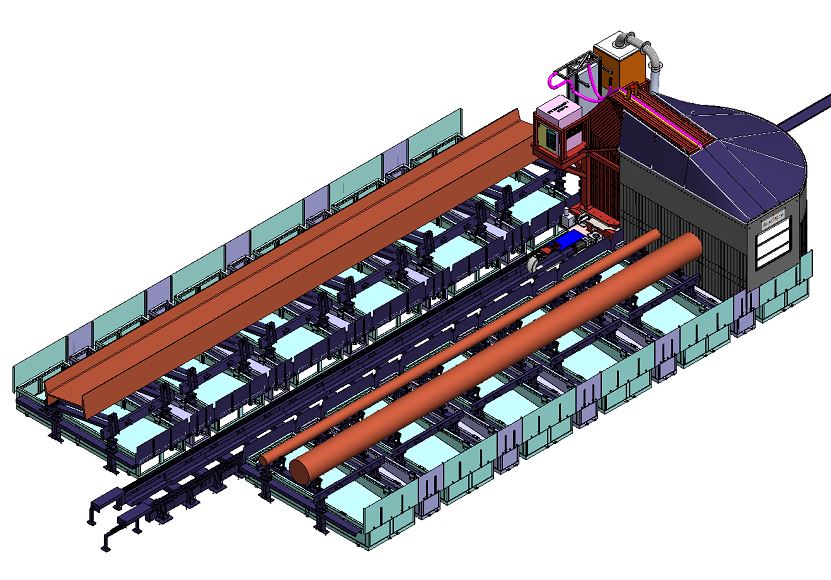

The RoboPlazma™ Universal System is a world first double work zone with integrated moving enclosure for various 2D and 3D cutting & welding. The System is capable of processing Structural steel for I beams, Channels, Angles, RHS, Square Tubes, Bulb bars, Pipe and plates (up to 30 mtr length through separate order). It is manufactured with highest quality standard components such as FANUC Robots, Precision Rails, Kemper, Germany fume extraction and Plazma source integrated with a user friendly RoboSwift Software interface that allows to create different programs with minimal operator intervention. All Robot axes are Servo driven for precision movement.

Modular hardware and software design allows you to add on Plazma cutting capability to enhance utilization of the system besides cutting. This unique flexibility gives users the potential to meet multiple customer needs simultaneously.

RoboPlazma™ expand beyond the competition to include,

Key Features of Universal System are;

- Double work zone eliminates material handling time

- Processing of I-Beams, Channels, Square and Rectangular Tubes.

- Produce high quality Bolt Holes, approved by AISC and CISC

- Bolt Hole sizes 2xThickness above 12 mm plate, No tool changing required.

- Produces all Standard and Non-Standard Copes.

- Produces Miter Cuts, Compound Miters and Double Compound Miters.

- 2D & 3D / multiple job processing capability.

- Simple 3 Click Programming

- Save valuable shop floor space.

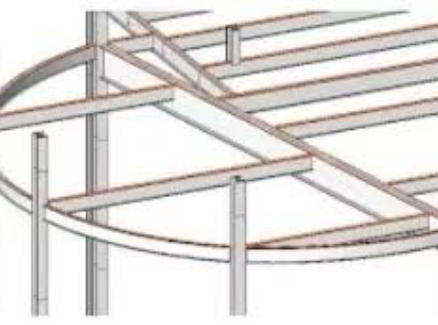

- Cutting Complex 3D Jobs such as, Dish end, Curved beam & Welded assemblies.

- Auto Nesting and cutting Large Plates.

- Automatic alignment of plate.

- Stitch Cutting capability.

- Single & Double Bevel.

- Higher Utilization and throughput.

- Minimum labor dependency

- Pipe Straight cut and Straight bevel.

- Produces Square Tube Slots for Knife connections.

- Beam Splitting and Beam Castellation.

- Produces lay-out on all sides.

- MIG/MAG Welding feature (optional) available.

Get in touch to know more about RoboPlazma