RoboSwift™ Welding Software

RoboSwift™ welding software solution conceptualized, designed and developed by Plazma Technologies Pvt. Ltd. India to operate with RoboPlazma™ systems. RoboPlazma™ along with RoboSwift™ delivers a solution for robotic MIG/MAG/TIG welding with minimal human intervention, controlling by itself the myriad components that work in the machine.

In the past Robots have always been difficult to program for welding, Labor intensive manual teaching or complicated off-line programming with numerous steps was required to create a robot program.

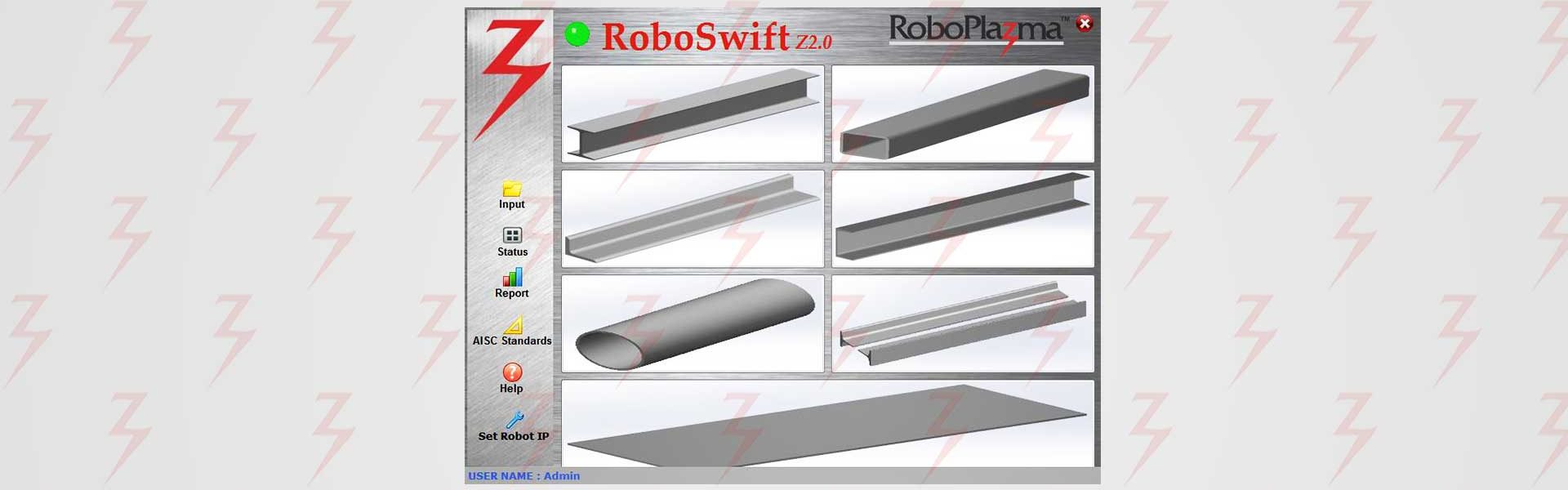

RoboSwift ™ is revolutionary software that works inside the controller to correct the errors of the robot. Inputs like DSTV, Auto Cad, iges, Step, Catia, Steel Grip etc. files are imported into RoboSwift™. These files are then combined with the internal welding process parameters and robot motion knowledge to output a ready to go execute program.

All the software intelligence such as various backend procedures, databases, weld parameters, self learning algorithms, geometrics, optimizers etc. is reflected in the final welding quality and precision, keeping all the processing of the backend invisible to the operator.

Key Features of RoboSwift™ Welding Software

- Simple and easy Offline programming

- Higher weld speeds and higher quality welding

- It generate multi-arm coordinated welding path

- Reduce start up time of arc welding robot

- Parametric Software module for different thickness

- TCP calibration software for torch calibration

- Work station and Tool change over function

- Arc Voltage sensing

- LAN / Ethernet connectivity