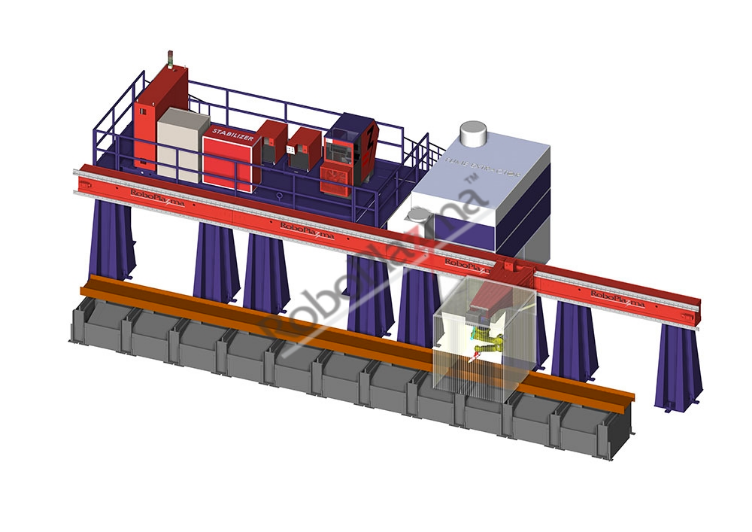

RoboplazmaTM Hot Plate System

World’s first Plazma Hot plate cutting System is up & running at JSL plant in India with 5000 tons hot plate cutting in record time.

Our Product - Roboplazmatm Hot Plate System

This is a world first. Even Siemens teams of steel plant builders were doubtful if this could be done. We were very fortunate that Jindal Stainless Steel believed in us due to our 16-year track record Plazma cutters.This is a world first. Even Siemens teams of steel plant builders were doubtful if this could be done. We were very fortunate that Jindal Stainless Steel believed in us due to our 16-year track record Plazma cutters.

RoboPlazma™ expand beyond the competition to include,

Key Features of Hot Plate System are;

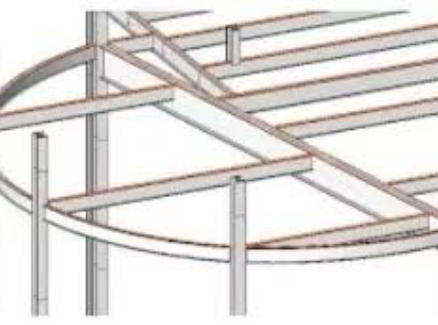

- Fully automated with S.V.A.I. plant

- Takes 7 minutes to roll a 75-meter hot strip. Earlier it took 1 month for shipping the cut plate to the customer, as job had to be cut twice, one a rough cut on the conveyor and then the final cut when plate is cold down. This lost a lot of material, increased inventory and of course reduced throughput.

- RoboPlazma™ cuts the plate directly on the conveyor just once.

- Intelligent algorithms recalculate the length every 10 sec due to rapid cooling of the plate.

- Completely unmanned system interfaced with the main SVAI control room.

- Self-checking &self-analyzing software that cross checks the system for every cut.

- Critical Online Intelligence compensates for the unpredictable behavior of hot steel like spring back and plate waviness.

- Hot Plate cutting at 1100-degree temperature.

- Achieves Right Angle Cut with misaligned plate with tolerance of +/- 1 degree o a Severely Bent Plate.

- Handles Plate Spring Back.

- Plant throughput Complete Automated Cycle.

Latest upgrades improve Productivity and safety:

- On line Hot Plate cutting.

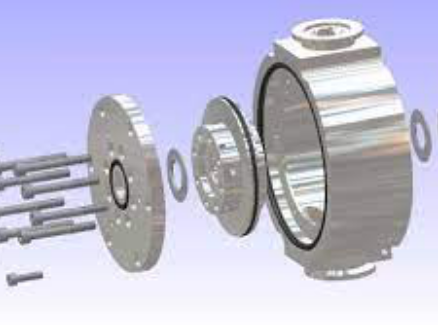

- Intelligent Touch sensing for alignment checking and auto- calibration of the Plazma torch

- 5000 tons Hot plate cut continuously.

- Controlled thru Profibus Plazma Technologies also initiated a comprehensive Production with Operation and Maintenance Training Program.

Get in touch to know more about RoboPlazma