Fabrication

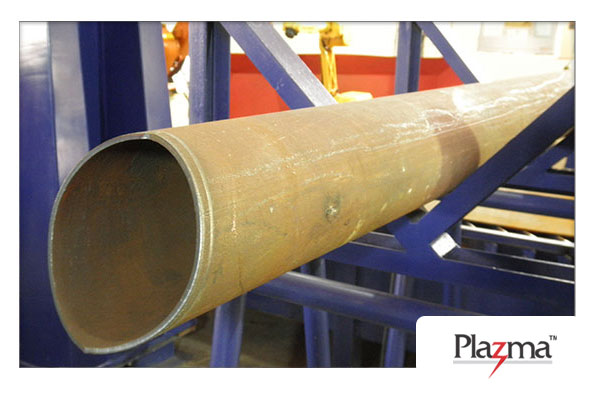

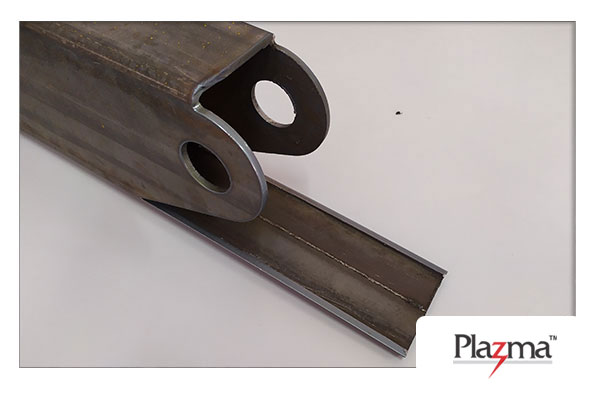

RoboPlazma™ is an ideal solution for small, medium and large Steel Fabricators that are looking for a single machine solution to fabricate I Beams, Channels, Angles, Tubes, Pipes and also have Large Plate processing covered with the same machine.

RoboPlazma™ is a One Stop Solution for the following fabrication

- Pre Engineered Buildings such as, Industrial Sheds, Shopping Malls, Offices & Housing complex

- Railway Bridge & Metro stations

- Indoor & Outdoor Stadiums

- Airports

- High Mass Towers

- Offshore Platforms

- Oil & Gas Refinery Platforms etc

RoboPlazma™ opened the doors to fully automated manufacturing for fabricators by minimizing material handling, drastically reducing labor and cutting costs increasing output. All this, while lowering capital investment in machinery, since one RoboPlazma™ system does it all.

In structural steel fabrication shop moving long, heavy structural members around your shop is difficult and costly. It does not add value to the product. Your client only pay for the finished fabricated product and is not bothered whether a beam was moved 15 times or 3 times in your shop.

RoboPlazma™ eliminates 90% of transfers and material handling. Finish parts are delivered to the fabricators and fit ups to boot productivity. Skilled labor dependency is reduced to almost minimum.

Each structural steel member has all its copes, slots, miters, bolt holes, notches, flush cuts, piece marks and layout marks made in one pass through RoboPlazma™. It’s fast, accurate and economical.

With RoboPlazma™, time and labor goes into welding and fit ups and not moving it around your shop for different operations.